sales@uv-ozonechina.com +86-311-89906694

sales@uv-ozonechina.com +86-311-89906694

Ozone generator is applied in water treatment engineering situations, there are many factors may affect the efficiency and reliability of the generator, so the ozone generator in the design application system must pay attention to the following questions:

(1) generator raw material gas is absolutely not containing hydrocarbons, corrosive gas and any other oxygen/ozone/corona reaction occurs in the environment, so as to harm or damage to equipment safety.

As is known to all, the explosion of the three elements is the fuel and oxidizer and fire, and ozone generator corona has been in existence in the environment of the two, namely, oxidant and fire.So you must prevent the raw gas containing hydrocarbon fuel material;If there is a possible hydrocarbons, must install a hydrocarbon analyzer, so that when the concentration of hydrocarbon close to the lower explosive limit (LEl) of 25% when cut off power supply.

Fluorocarbon compounds, such as teflon or coolant can break down to form fluorine in the corona, which can erode glass dielectric material, can accelerate the dielectric body damage.Around the corona on the surface of the outside circulation cooling fluid may through the seal leakage and into the space of corona, result in the dielectric body surface to form a layer of paint, coating.When this happens, because this kind of coating to reduce the ozone production efficiency, the dielectric body must be regularly cleaned.

In addition, feed gas should be about 5 microns filter out particles, to prevent small desiccant powder or other particles from entering the generator corona area.So as not to affect the corona efficiency.

Gas supply pressure can change without control, because of the influence of air pressure corona power induction and across the dielectric body, the applied voltage will make a wide range of pressure change generator operation unreliable.Is beyond the scope of corona power can cause fuse or breaker automatically disconnect.Beyond the applied voltage peak also can cause the dielectric body premature failure.

(3) the ozone generator system design, must be able to prevent a large amount of water into the generator.

Water seal gas compressor with the float valve or the air dryer condensate valve jam, cause generator corona indoor irrigation.Corona indoor large amounts of water can lead to corona high concentration, current density and local dielectric heating, dielectric body caused by premature failure.Even before the water into the corona chamber to cut off the corona detection device power, impurities in the water can also be deposited in the element on the surface, these impurities must be removed before continue to run.Operation failure or error can be forced to deal with water from ozone contact pool to flow to the generator, at least corona components will cause pollution or damage of the dielectric body.In addition, the system design and operation procedures must prevent flammable corrosive gas and touch the backflow of steam from the ozone into the generator.

(4) cooling water water quality is better, to prevent scale, lest affect generator cooling effect.

Two mining said of water-cooled generator, to make the scale, at least on the surface of the heat transfer of cooling water of the water quality is very important.Scale will lower the heat transfer efficiency, to reduce ozone production, increase maintenance costs.Technically tap water coolant is preferred, however, for large generator used in industry need water, use water economically unattractive, perhaps only a system with except in the case of water treatment plants.In contrast to tap water, generally treated sewage as cooling water, the effect is not very good, because it is easy to cause the scale formation.If the quality of water or other fluids in the sealed cooling circuit ten times, at the end of the level of heat exchanger is specially designed to be the least scale;And facilitate cleaning, and sewage water can also be used as the last stage radiator.To the best balance between water and equipment maintenance, system design most will use the high quality drinking water (cooling tower water or heat exchangers without the suspended solid, chloride < 5 mg/L).

5] for cooling gas generator, the cooling air must be free of moisture, impurities, corrosive, aerosol, oily or conductive material and visible dust.Under normal circumstances, unless in an extremely dusty industrial atmospheric environment, the air was probably don't need to filter processing.

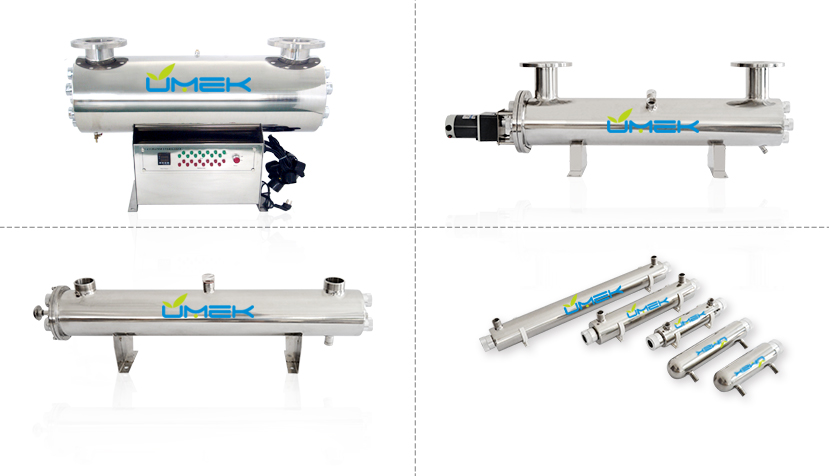

UMEK was established in 2010, with production, research and development, sales as one of the professional manufacturers of ultraviolet disinfection and ozone equipment, products cover drinking water, municipal water, sewage and other water treatment requirements. Email: sales@uv-ozonechina.com

Ultraviolet disinfection technology is very expeditious in destroying bacteria. UV energy can destroy bacteria and virus in just about 1-5 seconds. In order to reach the same disinfection effect, it costs about 30 minutes or more contact time byuse other chemical methods (Chlorine, Ozone, Chlorine Dioxide).

Ozone generatoris used for preparing ozone (O3) gas device.Ozone is easy to decompose, could not be saved to the scene for making field use (special circumstances can be stored for a short period of time), so those using ozone to place all needsto use ozone generator.

UMKE stock both quartz thimbles (domed at one end) and quartz sleeves (open at both ends) for Low Pressure and Medium Pressure reactor and sewage treatment municipal channel UV systems. Our thimbles and sleeves are made from pure fused quartz, allowingmaximum UV output from the UV lamp to the liquid.

TEL