sales@uv-ozonechina.com +86-311-89906694

sales@uv-ozonechina.com +86-311-89906694

1. Fenton oxidation process

The combination of ferrous salts and hydrogen peroxide is called Fenton, which can effectively oxidize and remove hard-to-degrade organic matter that cannot be removed by traditional wastewater treatment technology.

Features of Fenton oxidation process:

(1) Non-selective oxidation, strong ability to remove organic matter.

(2) The final decomposition of organic matter into CO2 and H2O, no toxic and harmful intermediates, safe and environmentally friendly.

(3) The pH value of the effluent needs to be between 2 and 4, and the effluent needs to be adjusted to acidic, and then adjusted to neutral at the end of oxidation.

(4) high unit consumption of chemicals required for complete COD degradation, resulting in high treatment costs.

(5) Rapid reaction time is short.

Fenton oxidation applications:

Fenton reagent oxidation method is difficult to be applied in large and medium-sized wastewater treatment plants because of the need to adjust acid and alkali, large unit consumption of chemicals, long reaction time and large sludge volume.

Fenton reagent oxidation method is suitable for small and micro sewage treatment plants with acidic incoming water, especially for acidic sewage treatment of some dyestuff, pesticide and pharmaceutical intermediate enterprises.

2. ClO2 catalytic oxidation process

ClO2 catalytic oxidation is one of the advanced oxidation technologies for water treatment, which is improved and developed on the basis of chemical oxidation method. The principle of chlorine dioxide catalytic oxidation is to catalyze the oxidation of organic pollutants in wastewater by using strong oxidant - chlorine dioxide under normal temperature and pressure in the presence of surface catalyst, directly oxidizing organic pollutants into carbon dioxide and water, or oxidizing large-molecule organic pollutants into small-molecule organic pollutants, improving the biochemical properties of wastewater, which can better remove organic pollutants.

Features of ClO2 catalytic oxidation process:

(1) ClO2 has a long-lasting oxidation capacity.

(2) The reaction of ClO2 with organic matter hardly produces fugitive organic chlorides and does not produce carcinogenic trichloromethane.

(3) The reaction with organic matter has remarkable selectivity, and the oxidation ability is highly correlated with the type of substituent on the organic matter. The use of high efficiency catalysts overcomes its selectivity for the oxidation of organics.

(4) degradation of organic matter is dominated by the generation of small molecule compounds with oxygen groups, which can increase the effluent BOD5 value and improve biochemical properties.

(5) The pH value of the effluent needs to be acidic (around 6), and the effluent needs to be adjusted to acidic, and then adjusted to neutral at the end of oxidation.

(6) Reaction time: in 45~60min.

ClO2 catalytic oxidation applications:

As the chlorine dioxide catalytic oxidation technology requires the pH value of the wastewater to be acidic (around 6), the wastewater needs to be adjusted to acidic, and then adjusted to neutral at the end of oxidation, which limits its application in large and medium-sized wastewater treatment plants.

In addition, because the reaction between chlorine dioxide and organic matter has significant selectivity, it is necessary to select a suitable catalyst, and the selection of catalysts in practice is complicated and difficult, which in turn limits its application in industrial wastewater.

At present, chlorine dioxide catalytic oxidation technology is successfully applied in the following fields.

(1) In the treatment of gas wastewater, high concentration cyanide wastewater, p-aminoanisole wastewater, phenol formaldehyde wastewater and printing and dyeing wastewater have achieved good results, can remove most of the difficult to degrade organic pollutants, and improve the biochemical properties of wastewater.

(2) It has good effect of decolorization and COD removal for water-soluble dyestuff such as cationic dyestuff, azo dyestuff and water-insoluble dyestuff such as sulfide dyestuff, which are easy to oxidize.

3.Ozone catalytic oxidation process

Ozone catalytic oxidation is the use of ozone in the role of the catalyst generated by the hydroxyl radical [-OH] oxidation decomposition of organic pollutants in water, because -OH oxidation capacity is very strong, and the oxidation reaction is not selective, so the rapid oxidation and decomposition of most organic compounds (including some highly stable, difficult to degrade organic substances).

Features of Ozone catalytic oxidation process:

(1) Extremely strong oxidation capacity for organic pollutants and removal of organic matter.

(2) the participation of catalyst, oxidation selectivity is greatly reduced, almost broad-spectrum application.

(3) The final decomposition of organic matter into CO2 and H2O, no toxic and harmful intermediates, safe and environmentally friendly.

(4) The pH value can be neutral or alkaline, no need to adjust the pH value of sewage.

(5) Ozone generator generates ozone by electricity and air, no chemicals, safe and hygienic on site.

(6) The oxidation reaction time is short, generally controlled at about 30min, and the reactor volume is small.

Ozone catalytic oxidation applications:

Because of the above characteristics, ozone catalytic oxidation technology is suitable for CODcr degradation in large, medium and small wastewater treatment plants with almost all nature of wastewater. Through the comparison of the above three oxidation processes, the ozone catalytic oxidation process has good treatment effect, wide application range and mature technology, and also has a large number of successful applications in wastewater treatment plants at home and abroad.

Ultraviolet disinfection technology is very expeditious in destroying bacteria. UV energy can destroy bacteria and virus in just about 1-5 seconds. In order to reach the same disinfection effect, it costs about 30 minutes or more contact time byuse other chemical methods (Chlorine, Ozone, Chlorine Dioxide).

Ozone generatoris used for preparing ozone (O3) gas device.Ozone is easy to decompose, could not be saved to the scene for making field use (special circumstances can be stored for a short period of time), so those using ozone to place all needsto use ozone generator.

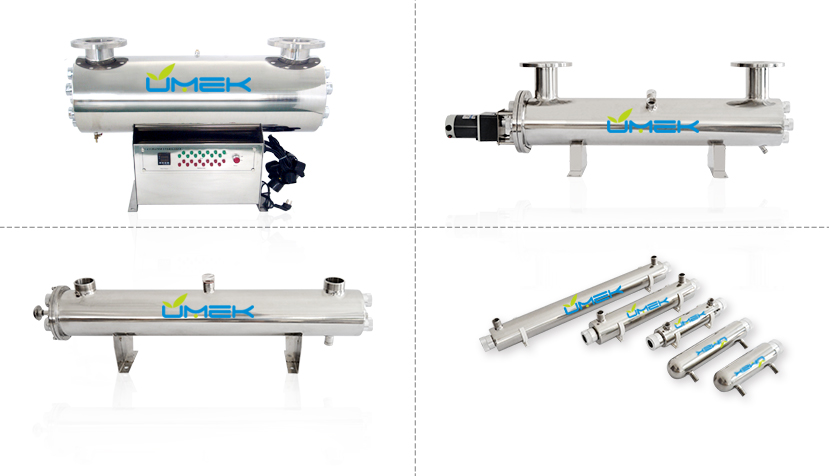

UMKE stock both quartz thimbles (domed at one end) and quartz sleeves (open at both ends) for Low Pressure and Medium Pressure reactor and sewage treatment municipal channel UV systems. Our thimbles and sleeves are made from pure fused quartz, allowingmaximum UV output from the UV lamp to the liquid.

TEL